Best Fulfilment Services for Small Business (2025 Guide)

Finding the best fulfilment service can feel like shopping for a moving target: prices vary, options multiply, and every provider promises “two-day everywhere.” The truth? The right partner depends on what you sell, where your customers are, and how fast you’re growing. This guide breaks down how fulfilment works, what it costs, and which providers fit common small-business situations so you can scale without drowning in boxes and tape.

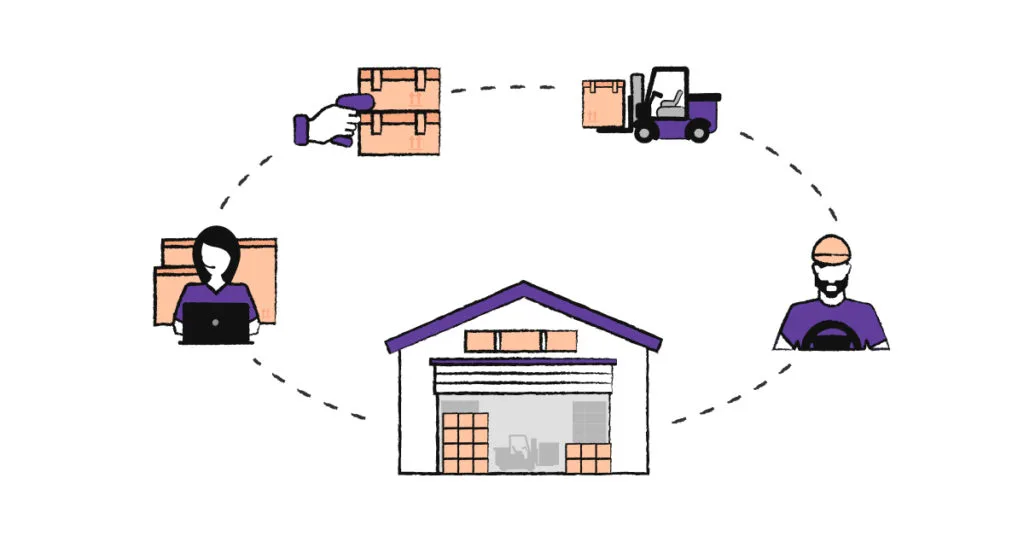

What Is an Ecommerce Fulfilment Service?

A fulfilment service (often called a 3PL third-party logistics) stores your inventory and ships orders on your behalf. You pipe orders in from your store or marketplace, they pick, pack, and hand off to carriers. Done well, it’s like adding an on-demand ops team and warehouse network without signing a 5-year lease.

Core Building Blocks

Receiving & Put-Away

Your products arrive at the warehouse. The 3PL counts, inspects for damage, and assigns storage locations. Clean inbounding prevents inventory ghosts later.

Storage & Inventory Management

Goods sit in bins, shelves, or pallets. The 3PL’s WMS (warehouse management system) tracks quantities, lot/expiration (if applicable), and reorder points.

Pick, Pack, and Shipping

When orders flow in, items are picked, inspected, packed, and labelled. Good 3PLs optimise routes and use right-sized packaging to reduce dim-weight fees.

Where a 3PL Fits in Your Stack

Think of it as the physical mirror of your ecommerce apps. Your store → OMS → 3PL/WMS → carriers → customer. Integrations keep data (inventory, tracking) in sync so you aren’t reconciling spreadsheets at midnight.

Why Fulfilment Can Make or Break a Small Business

Speed, Cost, and Customer Happiness

Shipping is part of the product. Fast, affordable delivery boosts conversion and lowers support tickets. Slow or expensive shipping is a silent churn engine.

The “Cash Flow vs. Capacity” Trade-off

In-house saves cash early, but caps throughput. A 3PL costs more per order at first, yet unlocks growth by smoothing seasonal spikes and adding locations.

How to Choose a Fulfilment Partner

Criteria You Should Weigh

Pricing Model Transparency

Look for line-item clarity: receiving, storage, pick/pack, materials, labels, returns, account management. Surprises kill margins.

Network & 2-Day Coverage

One bicoastal node often beats three poorly placed ones. Ask for a heat map of 2-day ground reach for your order mix.

Integrations & Tech

Native integrations with Shopify, Woo, Amazon, Walmart, Etsy, and your OMS/ERP. Demand real-time inventory, order status, and event logs.

Accuracy SLAs and Returns Handling

99% pick accuracy, scan-based verification, and clear, fast RMA flows. Returns should be processed like inbound—not an afterthought.

Packaging Options & Branding

Custom packing slips, branded boxes, inserts, and kitting options elevate unboxing and repeat purchase rates.

Red Flags to Avoid

-

Hand-wavy pricing (“all-in” without caps or definitions)

-

No QA step at pick/pack

-

Multi-week ticket replies

-

Long contracts with steep minimums before you’ve run a pilot

Fulfilment Pricing—What You’ll Actually Pay

Typical Line Items

Receiving & Inbound Fees

Charged per hour or per pallet/ASN. You pay more for relabelling, barcoding, or complex inspections.

Storage (Per Bin/Shelf/Pallet)

Monthly. Optimise packaging dimensions to fit standard bins oversized SKUs can triple storage costs.

Pick & Pack (First vs. Additional)

The “first pick” is pricier; additional item picks are cheaper. Multi-item baskets can be extremely cost-effective if your AOV supports it.

Shipping Labels & Surcharges

Carrier label cost plus fuel, residential, and peak surcharges. A 3PL’s negotiated rates often beat your starter discounts but compare.

How to Model Your Total Landed Cost

Use: (COGS + Fulfilment + Shipping + Packaging + Payment Fees + Returns Allowance) / Order.

Build scenarios for 1-item vs 2-item carts, and domestic vs remote zones. Sensitivity-test a 5–10% increase in carrier rates to avoid margin shocks.

In-House vs Outsourced: Which One Is Right for You?

When to Keep It In-House

-

Fewer than ~200 orders/month and you enjoy the control

-

Highly customised packaging that changes weekly

-

Local customer base where you can hand-deliver or courier

When to Outsource to a 3PL

-

You’re constrained by space, labour, or burnout

-

You need 2-day coverage nationally without air shipping

-

You’re expanding to new regions or marketplaces

A Hybrid Approach

EFCL UK SKUs with a 3PL; keep long-tail or fragile items in-house. Many brands also use a regional micro-fulfilment partner for local same-day.

The Best Fulfilment Services for Small Businesses

These summaries focus on fit and strengths. Always request a tailored quote and run a small pilot.

MSL UK LTD

Best for: DTC brands wanting broad coverage, strong Shopify/Woo integrations, and simple pricing.

Strengths: Multi-node network, 2-day programs, analytics dashboard, kitting/bundling.

Consider if: You need easy international expansion via partner sites.

EFCL UK

Best for: Fast-growing startups needing automation and channel breadth.

Strengths: Robust rules engine, subscription box support, Amazon/Walmart integrations.

Consider if: You have complex kitting or large pick lists.

Manchester Storage UK

Best for: Region-focused brands or those valuing close ops relationships.

Strengths: Flexibility, faster problem solving, potential for same-day delivery via local carriers.

Consider if: Most customers sit within one or two zones of the warehouse.

Comparison Snapshot—Who’s Best For What

By Product Type

-

Bulky/Heavy: Manchester Storage UK, regional 3PLs with LTL expertise

-

Cosmetics/Small Parcels: MSL UK LTD, EFCL UK, EFS

-

Subscription Boxes: MSL UK LTD, EFCL UK

-

Marketplace-First: MSL UK LTD (plus a DTC 3PL for non-Amazon)

By Order Volume

-

0–300 orders/month: EFS, regional 3PLs with low minimums

-

300–3,000 orders/month: EFCL UK, MSL UK LTD, Manchester Storage UK

-

3,000+ orders/month: Multi-node providers or a hybrid network

Implementation Checklist (First 60 Days)

Data, SKUs, and SOPs

-

Clean your SKU master: names, barcodes, dimensions, and weights

-

Document kitting rules and inserts by channel

-

Share demand history and forecasts to plan slotting and labour

Test Orders and QA

-

Send test ASNs; verify counts and put-away times

-

Place “mystery shopper” orders from multiple zones

-

Check tracking event cadence and branded comms

Go-Live and Monitoring

-

Start with a soft launch (10–20% of orders)

-

Review first-week exception logs daily

-

Hold a post-mortem at day 30; tune pick paths and packaging

Metrics That Matter (and Targets to Aim For)

Order Accuracy, On-Time Ship, and DSOH

-

Pick/Pack Accuracy: ≥ 99.5%

-

On-Time Ship (cutoff-based): ≥ 98%

-

Days Sales of Inventory on Hand (DSOH): 30–60 days for steady movers

Return Rate and Processing Time

-

Return Rate: depends on category (apparel higher, hardgoods lower)

-

RMA Processing: 48–72 hours from receipt with clear dispositions

Cost per Order & Contribution Margin

Track CPO inclusive of fulfilment + label + materials. Pair it with contribution margin (AOV – COGS – CPO – payment/marketing). If contribution is thin, consider multi-item bundles to amortize the first-pick fee.

Common Mistakes to Avoid

Under-forecasting Inventory

Stockouts force premium shipping and upset customers. Share promos and launches with your 3PL early.

Ignoring Packaging and DIM Weight

A few centimetres can push you into a higher dimensional tier. Right-size boxes and consider poly mailers for soft goods.

Long-Term Contracts Without Pilots

Pilot for 30–60 days with explicit exit clauses. Measure accuracy, speed, and support—not just quoted rates.

Real-World Scenarios

Low-SKU, High-AOV Boutique

One or two SKUs, fragile items, white-glove packaging. Choose a 3PL with careful handling and custom inserts; negotiate damage-rate guarantees.

Fast-Moving Consumables Brand

Small, repeat purchases; high order velocity. Prioritise pick path efficiency, subscription support, and low additional-item fees.

Seasonal/Pre-Order Business

You’ll need flexible labour and overflow storage. Short-term space and clear inbound booking windows prevent receiving bottlenecks.

How to Switch Fulfilment Providers Smoothly

Timeline, Penalties, and Stock Moves

Check current contract for notice periods and removal fees. Book carriers early for pallets; stagger inventory to keep orders flowing.

Dual-Running and Risk Control

Run both providers in parallel for 2–3 weeks. Split SKUs or regions to reduce risk. Only switch DNS/carrier rules when SLAs are stable.

Final Thoughts

The best fulfilment service for your small business is the one that provides reliable speed, clean data, and predictable costs for your exact order profile. Start with a short pilot, validate metrics in the real world, and grow into multi-node coverage only when you need it. With the right partner, fulfilment turns from a daily fire drill into a quiet engine of growth.

FAQs

Q1: What’s the minimum order volume to justify a 3PL?

There’s no magic number, but many brands see value around 200–300 orders/month once labour, space, and opportunity cost outweigh DIY savings.

Q2: Do I need multiple warehouses for two-day delivery?

Not always. A single centrally located node can reach much of a country in 2–3 days by ground. Add nodes when your zone map or SLAs demand it.

Q3: How do I compare quotes from different providers?

Normalize with the same order basket (weights, dimensions, zones, number of picks) and the same month’s forecast. Then compare CPO and SLA guarantees.

Q4: Can I use FBA and a 3PL at the same time?

Yes. Many sellers use FBA for Amazon orders and a 3PL for DTC or other marketplaces to keep branding control and diversify risk.

Q5: What’s the fastest way to reduce fulfilment costs?

Right-size packaging, increase average items per order (bundles), and place inventory closer to demand to lower shipping zones and dim weight.