How to Optimise Your Pick and Pack Process in Ecommerce Fulfilment

In the fast-paced world of ecommerce, delivering orders accurately and on time is crucial. Whether you operate your own fulfilment centre or rely on 3PL (third-party logistics) warehousing, an efficient pick and pack process is vital for customer satisfaction and business growth.

This comprehensive guide outlines practical steps to streamline your pick and pack operations, incorporating the latest solutions in 3PL UK services to boost your logistics performance.

Step 1: Evaluate Your Existing Pick and Pack Workflow

Before implementing improvements, start by reviewing your current processes. Identify weak points in your warehouse logistics that are causing delays or errors. Key areas to examine include:

- Slow order picking due to disorganised inventory

- Frequent fulfilment mistakes caused by manual errors

- Packaging bottlenecks leading to delayed dispatch

A thorough audit will help pinpoint inefficiencies that hinder performance.

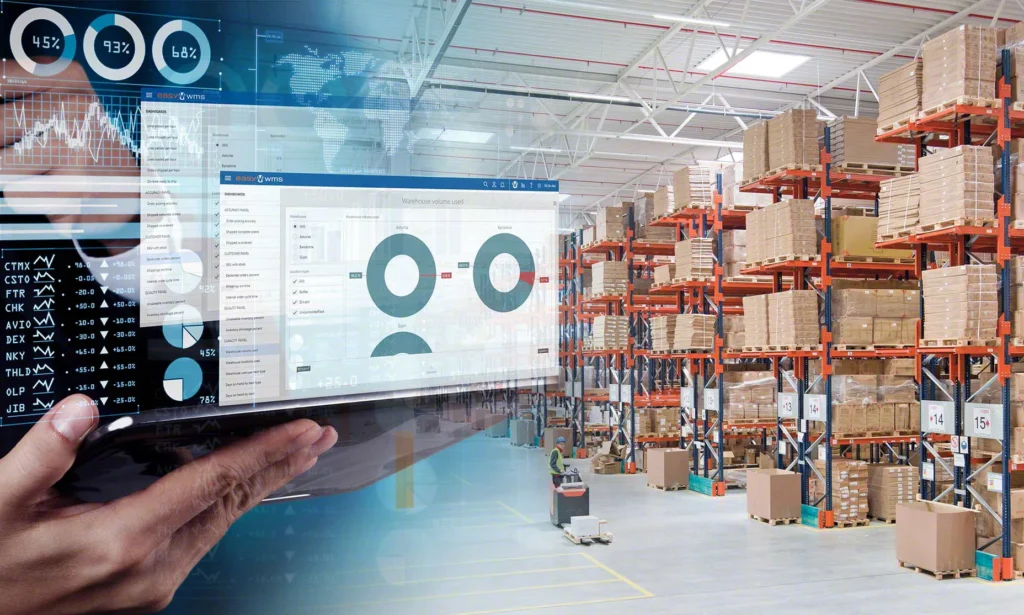

Step 2: Implement a 3PL Warehouse Management System

Upgrading to a modern 3PL warehouse management system (WMS) can revolutionise your operations. This software allows for:

- Real-time inventory tracking

- Automation of routine tasks

- Seamless integration with platforms like Shopify or WooCommerce

A reliable 3PL logistics warehouse system improves visibility, reduces errors, and enhances operational efficiency.

Step 3: Optimise Your Warehouse Layout

An organised warehouse layout is key to faster picking and packing. Aim for a setup that promotes a smooth flow of goods from inbound receiving to outbound shipping. Best practices include:

- Installing warehouse pallet storage racks for space efficiency

- Creating clearly labelled zones for different SKUs

- Designing a logical pick path to minimise walking time

Streamlining the physical environment can significantly improve picking speed and accuracy.

Step 4: Provide Ongoing Staff Training

Your warehouse team plays a critical role in fulfilment success. Continuous training ensures that they follow best practices and adapt to system upgrades. Training should focus on:

- Efficient picking methods to reduce delays

- Accurate labelling and packaging to prevent errors

- Quality control awareness to uphold standards

A skilled team ensures smooth operations and high customer satisfaction.

Step 5: Improve Labelling and Packaging Processes

Efficient labelling and packaging enhance the final leg of your fulfilment journey. To reduce errors and shipping delays, consider:

- Using custom packaging tailored to your product types

- Sourcing durable packaging boxes from trusted suppliers like Globe Packaging UK

- Implementing automated labelling systems to cut down on manual labour

Proper packaging not only protects products but also leaves a lasting impression on customers.

Step 6: Leverage Professional 3PL Fulfilment Services

Working with an experienced 3PL fulfilment provider can transform your ecommerce logistics. These companies handle:

- Inventory storage

- Order picking and packing

- Nationwide or international shipping

Outsourcing to a trusted fulfilment services UK provider allows you to focus on growth while they manage day-to-day logistics.

Step 7: Monitor KPIs and Continuously Optimise

Once changes are in place, track key performance indicators (KPIs) to measure success. Essential metrics include:

- Order accuracy rate

- Average time per order pick

- Shipping and delivery speed

Use this data to make informed adjustments and drive continuous improvement in your pick and pack process.

Conclusion

Streamlining the pick and pack process is fundamental to ecommerce fulfilment success. By auditing your current operations, adopting advanced 3PL technologies, and improving staff efficiency and warehouse layout, you can deliver a seamless customer experience. Whether managing your own fulfilment centre or partnering with a 3PL warehouse UK provider, these strategies will enhance both your logistics performance and your bottom line.

FAQs About the Pick and Pack Process

What is the pick and pack process in ecommerce?

The pick and pack process involves retrieving items from warehouse inventory (picking) and preparing them for shipment (packing). It’s a crucial part of order fulfilment in ecommerce.

How can I speed up the pick and pack process?

Speed improvements come from better warehouse layout, automation through WMS, clear labelling, staff training, and minimising handling time by grouping similar orders.

What are common mistakes in pick and pack operations?

Frequent errors include selecting the wrong items, mislabelling parcels, using unsuitable packaging, and poor stock organisation.

Is it better to use a 3PL for picking and packing?

Yes, partnering with a reputable 3PL fulfilment company can save time, reduce errors, and improve delivery speed especially as order volume grows.

Can I integrate my ecommerce platform with a 3PL provider?

Most modern 3PL providers offer seamless integration with popular ecommerce platforms like Shopify, WooCommerce, and Amazon for real-time inventory and order syncing.